Able Aerospace Completes 98% of Work In-House – What Does That Mean for Customers?

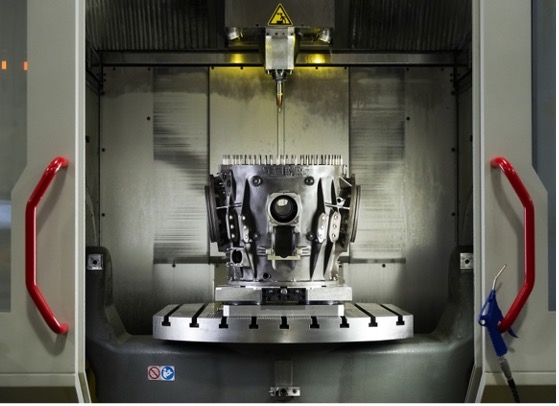

At Able Aerospace, 98% of all work is completed within our 250,000-sq.-ft. facility, which helps eliminate delays that come with outsourcing, and allows us to significantly reduce turnaround time and help keep our customers’ aircraft flying.

Our facility, headquartered in Mesa, Arizona, is equipped with advanced capabilities that allow us to manage a wide range of processes. These include machining and grinding, chemical processing, paint, non-destructive testing (NDT), hydraulics, cold spray, and shot peen. Each of these processes play a vital role in delivering comprehensive maintenance, repair, and overhaul solutions efficiently and effectively.

Because each critical process is housed under one roof, the team can quickly evaluate a component’s condition, determine the required repairs, and move it directly into the next process without delay. Whether the part requires material restoration, surface enhancement, or specialized treatment, having these capabilities in‑house enables a seamless progression from evaluation to repair. This tighter workflow reduces hand‑offs, minimizes downtime, and helps keep each job moving steadily through the repair process.

This level of integration is the result of decades of investment in talent, technology, and innovation. It allows us to approach every job with precision and accountability, ensuring that work is completed to the highest standards.